Hydraulic Structures

One of the keys in the field of hydraulic engineering is waterproofing, which is directly related to the durability and serviceability of the structure.

Understanding of the cause of possible leakage, identification of the most efficient waterproofing configuration and its implementation/execution require specific competence and expertise. For selecting the most appropriate waterproofing solution a detailed knowledge of all state-of-the-art waterproofing systems and materials is of upmost importance.

As a Specialist Contractor for waterproofing geomembrane systems as well as for liquid-applied coatings, joint sealings, external waterstops, full face treatment of joints/cracks and all kind of grouting works, our competence is dedicated to rehabilitation and new construction of dams, pumped storage schemes, canals, reservoirs, hydraulic pressure tunnels, and shafts, but also ponds, snow storage basins, potable water tanks, sprinkler tanks, sewers, and wastewater treatment plants.

Materials & Systems

Exposed or covered polymeric geomembrane systems according to EN 13362 or EN 13362, as geocomposite, multi-layered, homogeneous or reinforced have been used at hydraulic structures as rehabilitation and mitigation technology for several decades. Since the layer is relatively thin at the same time extremely flexible it is preferred of absorbing settlements and deformations.

As a full-service provider, we support your project all along the way. From the planning, through material supply up to the professional installation of your sealing system.

To address the increasing demand for clean water, the challenge of water shortage and worldwide water pollution, stringent regulations and standards for water facilities have been implemented. Renesco is committed to valuable contributions with construction and refurbishment solutions to build water retaining structures better.

We are a frequently controlled certified installer operating under the strict German §19l WHG (Federal Water Act) for the installation of geosynthetics. Also, we are certified according to OENORM S 2078 for the installation of system components in landfills.

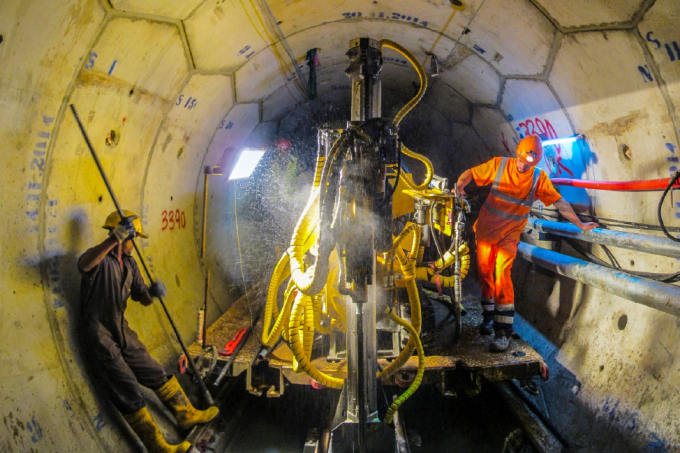

Injection & Grouting

Injections are becoming increasingly indispensable as a structural measure in foundation engineering as well as in underground mining. The possibility of being able to influence the subsoil properties of soils and the ground-/rock structure with the goal to achieve an intended structural engineering concept opens important economic and technical perspectives.

Renesco provides a comprehensive range of construction services specializing in cementitious and chemical grouting. We offer a complete package that includes material technology, equipment know-how, digitalization, real-time monitoring, specific drilling works and on-site practice.

As a member of the Marti Group, Renesco benefits from the in-house expertise as a multidisciplinary organization with services ranging from small hydraulic engineering projects to build pumped storage schemes. This applies to planning and design as well as to construction itself.

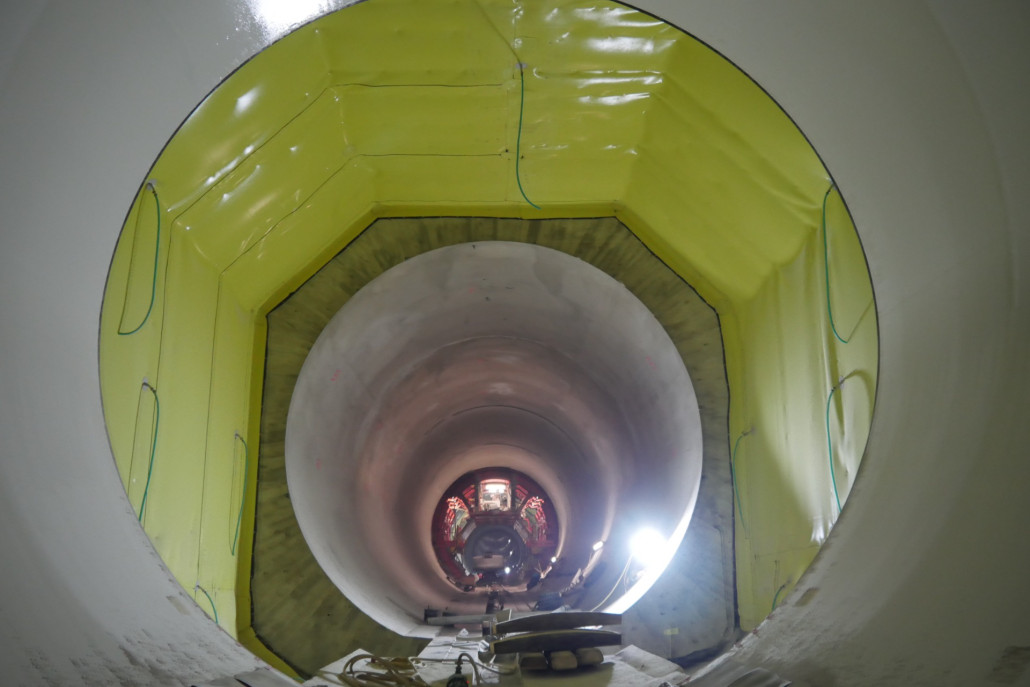

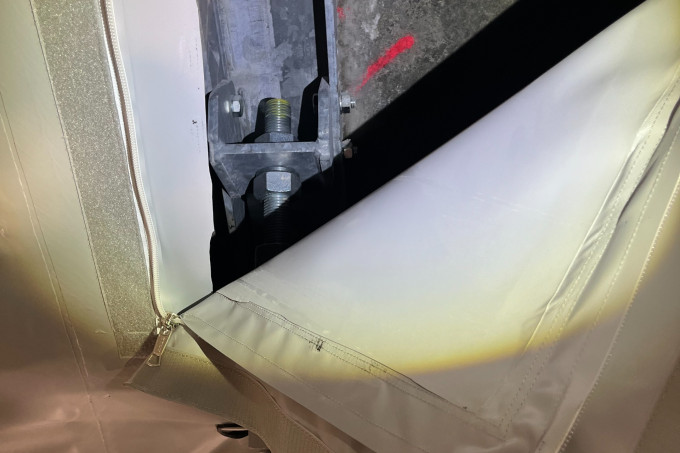

DRIP SHIELD

The term "drip shield" is referring to suspended fabrics installed beneath the roof area to collect potential water drips from the crown, thus preventing from any leakage over the equipment and slabs. The cloth is a polyester reinforcement geomembrane coated with PVC, with a unit weight of 700 g/m² (approx. 0.6 mm thick), with a high tear and tensile strength, as well with a high fire/smoke resistance class. The membrane sheets are jointed together by thermal welding to guarantee a waterproof seal.

The construction itself is an economical solution. The lining is fastened to a steel wire arched frame which is bolted into the stable rock or shotcrete lining and forms the theoretical profile. All fabrics are stretched by PE ropes to avoid water pockets and to give an aesthetical visual appearance. With the presence of manholes that opens with zippers or velcro it gives a personal access for visual inspection of the covered area/substrate.

A proven track record is given in various areas like underground structures, rock caverns, powerhouses, machine & transformer halls, or galleries.

WATER & SPRINKLER TANKS

Various internal waterproofing systems that are in direct contact with potable water must fulfill stringent requirements regarding hygiene, durability, exposure & stress conditions, construction method & sequence, ease of application and total cost management.

New or existing tanks and reservoirs to store potable waters are made of concrete or steel structures built above ground or below ground. Water towers in flat country sides or caverns in mountainous areas at elevated levels secure hydraulic pressure in water supply pipe network. All these solutions are designed to meet the specific needs and requirements of owners, architects, engineers and contractors on site.

Sprinkler systems are an integral part of hospitals, shopping centers and office buildings. Tightness is extremely important in these systems, otherwise there could be serious consequences for people and the building structure. The tightness of sprinkler tanks is a challenge. Connections, openings and attachments must be professionally connected to the applied sealing membrane.

B25 Water Tower BA1 (D), Polymeric Sheet Membrane.

DAMS, PUMPED STORAGE SCHEMES, RESERVOIRS & CANALS

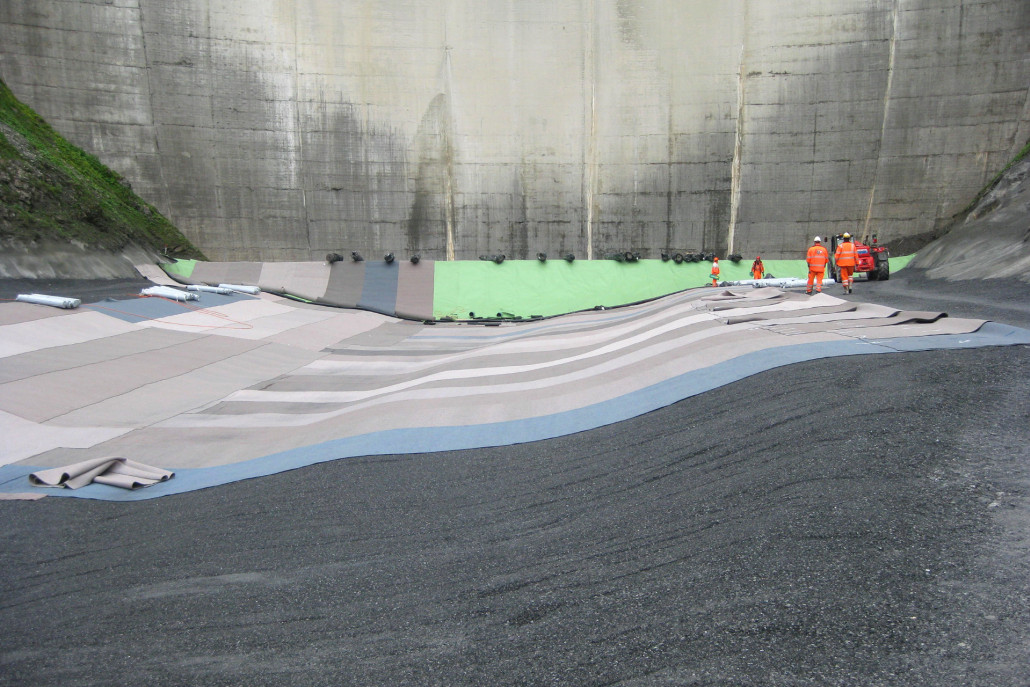

The use of geomembrane systems allows safe and reliable construction. They provide a watertight barrier that can withstand large settlements in the dam body and between the dam body & concrete structures, can resist the rapid flow of water, high/low temperatures and aggressive UV rays; can withstand seismic loading, allow steepening of the slopes and reduce the volume of fill and the construction times. They can be installed following construction of stages of the dam, placed on rough subgrades and steep slopes and allow important savings to the overall cost of the project.

In case of unlikely maintenance, repair of the thermoplastic geomembrane systems is rapid and can also be carried out underwater.

Among available upstream water barriers, the exposed geomembrane solution adopts a drained synthetic geomembrane system mechanically fixed to the upstream face of the dam. By using a face anchorage via tensioning profiles possible winkles, formation of slack areas and folds can be reduced increasing the material durability, give stability to the liner against wind suction, water level variations, and waves.